Most teams define a “good manual” as clear writing and clean design. In global manufacturing, that is only half of release quality. The other half is release control: the specification and compliance elements that must be correct at the final PDF gate—issue date, revision, required statements, barcode/QR integrity, and other seemingly minor fields that can stop shipping, weaken audit trails, and trigger costly rework.

This article explains what those last-gate checks look like in practice, why they matter, and how we systematize them to protect global releases.

Small Errors, Large Consequences

Consider a barcode. In an automated production line, it is the identifier that matches a product and its manual. If the barcode is wrong and the manual escapes into packaging, the result can be a mix-up incident: Product A shipped with Product B’s manual. This can trigger rework on already packed units—opening cartons, replacing inserts, and re-sealing thousands of boxes waiting for shipment or already in transit.

In digital distribution, the failure modes are equally damaging. A consumer scans a QR code and sees “404 Page Not Found,” or downloads a manual for the wrong model. The issue is not reading experience. It is release integrity.

The same applies to issue date and revision (Rev) control. If a safety incident occurs, these metadata fields can become critical evidence that the manufacturer provided the right safety information at the right time. If the issue date or Rev is wrong, it weakens the audit trail and increases exposure to claims that instructions were defective or not properly controlled. A single digit can undermine credibility when it matters most.

Poor explanations inconvenience users. Specification failures can halt business.

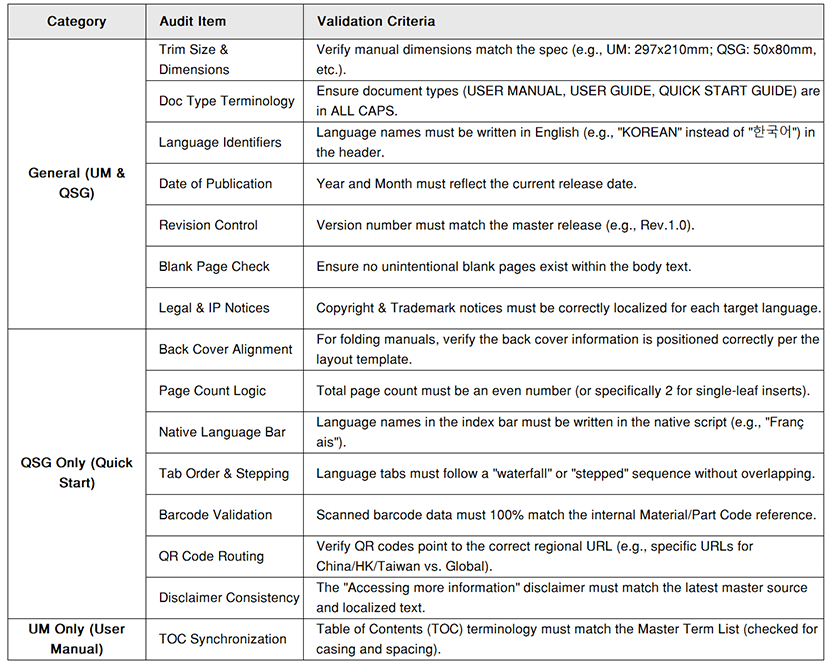

Why a Centralized Release Checklist Matters

A release-stage manual must pass a set of non-negotiable checks: the “must be correct” items that protect shipment, compliance, and liability posture. The list grows quickly as product variants and languages increase, because many checks must be verified per language and per output format.

The principle is simple: collect release-critical items, centralize them, and enforce them consistently. If these checks are handled informally across individuals—without a controlled checklist and a repeatable method—the probability of escape errors rises sharply.

Why Release QA Sentinel Exists

When documentation is released across dozens of languages and includes multiple regulatory statements and digital identifiers, the biggest risk is human error. Even with experienced reviewers, manual cross-checking of hundreds of PDF pages still creates inherent failure points: repetition, fatigue, and small differences that are easy to miss—especially when reviewers constantly switch between the PDF and reference files (approved URL lists, part-number tables, country statements, and more).

Hansem Global has supported global manufacturers’ manuals for more than 35 years. We converted those release-stage lessons into a repeatable system and built Release QA Sentinel—a core component of our QA Suite designed to validate specification and release-control elements at the final PDF stage.

How Release QA Sentinel Works

Release QA Sentinel validates both physical layout specifications and digital integrity elements in the final PDF. Two examples:

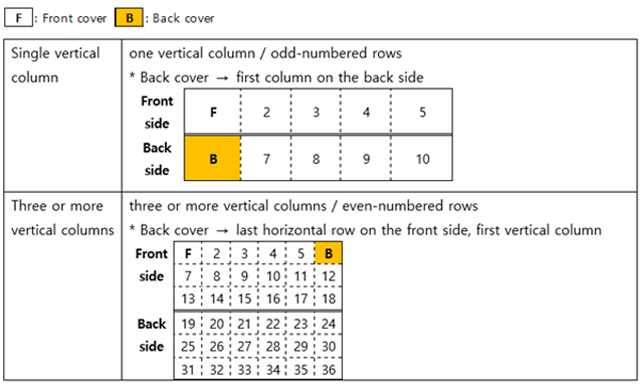

Folded Quick Start Guide back cover position validation

For folded printed manuals, back cover placement is release-critical. A position mistake can force a full reprint. Release QA Sentinel uses fixed anchors (elements with known placement) to calculate panel positions based on folding rules, then automatically determines whether the back cover is placed correctly. The report highlights any failures with page-level detail for fast correction.

Automatic QR and DataMatrix verification

Release QA often requires verifying both the presence of QR/DataMatrix codes and the correctness of the URLs they resolve to. Manual scanning becomes slow and error-prone as the number of codes grows. Release QA Sentinel automatically detects embedded codes and validates URL correctness against project rules (approved domains and path patterns). It flags failure modes that become immediate post-launch incidents: 404 links, wrong-model destinations, and rule-violating URLs. Reports record expected vs actual outcomes and pass/fail status.

Audit-Ready Reports and Evidence Logs

Each check produces a clear decision (pass/fail) and an evidence trail (inspection logs). This shifts release QA from “reading everything” to “reviewing exceptions,” so reviewers spend time on what requires judgment rather than repetitive searching and manual comparisons.

Measured Results: Faster Release QA, Higher Confidence

In production use, Release QA Sentinel has significantly improved efficiency and consistency. For a Quick Start Guide release gate, a manual inspection that typically required about 10 minutes was reduced to about 1 minute—roughly a 90% time reduction—by applying the same core checklist items at the final PDF stage. Across a checklist of approximately 30 items, more than half were automated, reducing reference-file navigation and minimizing manual comparison mistakes.

Most importantly, Release QA Sentinel standardizes inspection quality independent of individual fatigue or experience, and preserves an audit-ready record of what was checked and why it passed.

Hansem Global’s Commitment

Hansem Global is a Korea-based language services and technical documentation company with 35 years of experience supporting global manufacturers in IT, consumer electronics, and automotive programs. We are ranked No. 49 in CSA Research’s 2025 global Top 100 LSP list.

We do not treat manuals as “documents to deliver.” We treat release documentation as a controlled system. Alongside strong information design and user-facing clarity, we rigorously manage the small specification elements that can stop a launch—using proprietary QA tools, including Release QA Sentinel.

If your global manuals must be launch-aligned, compliance-ready, and release-controlled across languages and formats, Hansem Global is built for that standard.